“A revolutionary cooling solution for the challenges of a warming planet”

Maxwell™®

Heat Transfer Fluid

What is maxwell™?

Maxwell™ is an engineered suspension of sub-micron aluminum oxide particles in a base fluid of water or water/ glycol (“nanofluid”). Maxwell™ is a drop-in additive for cooling and heating systems, that works by enhancing heat transfer and thereby significantly reducing energy consumption and carbon emissions.

Maxwell™ is named after James Clerk Maxwell the pioneering Scottish scientist who in the late 19th Century discovered that adding metallic particles to water improved thermal energy transfer, thus creating the world’s first heat transfer fluid.

Over a century later, Maxwell™ is our patented implementation of this discovery, allowing systems using closed hydronic loops to benefit from the thermal properties of stable suspensions of metallic nanoparticles.

How Does Maxwell™ work?

Maxwell™ is an innovative heat transfer nanofluid additive which dramatically improves the energy efficiency of hydronic cooling & heating systems. A drop in heat transfer fluid for water based cooling & heating systems that improves heat transfer by up to 15%.

Water (or a water/glycol mix) is circulated from the chiller in a closed evaporator loop to Air Handling UJnits (‘AHU’). Maxwell™ increases the transfer of heat in the chiller evaporation cycle, reducing compressor “lift” or work and thus, the consumption of electrical energy.

Maxwell™ also increases thermal energy transfer in the AHU coils, which allows for higher chilled water set points, and lower fluid and air flow rates through pumps and fans, reducing their electrical power consumption.

Maxwell™ can also be used in a closed condenser circuit but not with an open cooling tower.

Sustainability Impact of Using Maxwell™

With companies trying to meet stringent sustainability targets, Maxwell™ is a simple, low-cost method for delivering a meaningful impact across a wide range of applications and industries.

Because of Maxwell’s efficiency, the cost of a typical installation is generally paid back within 1 – 2 years, depending on the utilisation rate of HVAC equipment and the local costs of electricity/natural gas.

The Benefits:

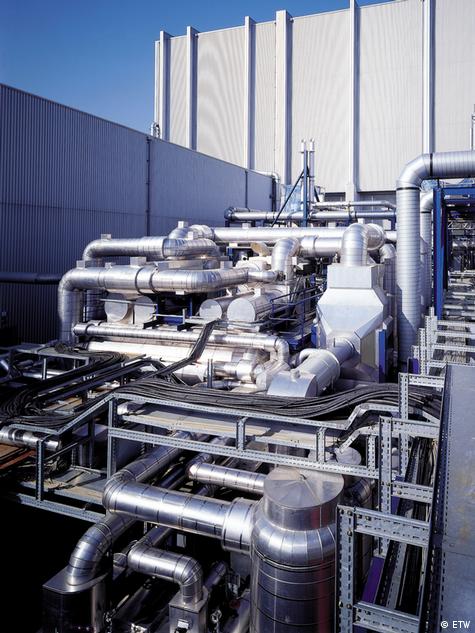

Applications

chillers

Maxwell™ typically increases heat transfer in the chiller evaporator by 12.5 % to 15%, reducing compressor lift (work) and electrical energy consumption.

Maxwell™ can also be used in a closed condenser circuit with a closed cooling tower, which provides for a similar increase in efficiency on the other half of the chiller’s refrigerant cycle.

For air or water-cooled chiller systems, Maxwell™ performance increase will result in more efficient equipment selection, reduced equipment room (MER) size, electrical service sizing and more.

Heat Pumps

Maxwell™ increases the heat transfer from the outside air or condenser fluid to the system fluid through the heat exchanger.

This increase in heat transfer reduces compressor lift by 12.5 % to 15%. In colder climates, many HVAC systems add glycol to the base fluid for freeze protection, which has the effect of reducing the thermal energy transfer which is referred to as the “glycol penalty”. Maxwell™, by increasing the thermal energy transfer, will substantially offset this “glycol penalty” in existing buildings. Additionally, when Maxwell is implemented during the design phase of new buildings, it can materially reduce the size of HVAC equipment, again reducing costs.

Energy Recovery Systems

Energy recovery systems are designed to save energy and reduce heating and cooling loads on an HVAC system. In the typical situation where no cross-contamination is required, a run-around loop is the system of choice. When added to the run-around loop, Maxwell™ increases heat transfer at the exhaust fan recovery coil and air handler pre-heat / cool coil by 15% or more allowing the fluid pump to run on lower flow rate/power.

Pumps, Fans & Terminal Units

Maxwell™ increases thermal energy transfer throughout the hydronic system. Fan coil and air handling units, system pumps and supply fans, can operate on lower power without compromising comfort.

The Solution

• Patented Innovative heat transfer nanofuild additive

• Effective in any closed – loop water or water/glycol – based system

• Suitable for cooling, heating and process applications

• comprises only 2% of total system fluid volume

Delivering Instant Results

• Up to 15% energy reduction

• Competitive 1 – 2 year payback period

• Lower carbon emissions

• Increase in HVAC system capacity

Simply & Safely

• Guaranteed lifespan of 10 + years

• No downtime … simple drop in additive

• Non corrosive and non toxic

Industries Benefiting From Maxwell™

Office Buildings

Chillers, heat pumps and associated mechanical systems will operate more energy- efficient with Maxwell™ added to the system. Maxwell™ is a simple, instant and cost-effective way for building owners and property managers to reduce energy costs and meet regulatory green initiative targets.

Data Centers

Chillers, heat pumps and associated mechanical systems will operate more energy- efficient with Maxwell™ added to the system. Maxwell™ is a simple, instant and cost-effective way for building owners and property managers to reduce energy costs and meet regulatory green initiative targets.

Health Care

Hospitals, research and pharmaceutical facilities require high quantities of outside air intake and generally operate 24/7/365. Maxwell™ allows chillers, heat pumps and energy recovery systems to operate more efficiently, reducing energy costs and maintenance requirements while extending equipment life.

Manufacturing

Maxwell™ can be used in HVAC systems that provide environmental cooling and heating to manufactur-ing areas. Certain manufacturing processes may be able to use Maxwell™ in closed chilled water loops that serve production equipment requiring cooling.

Warehousing

Most warehouses and logistic centres use a combination of chillers and adiabatic cooling. Any closed loop hydronic systems can use Maxwell to reduce the energy consumption of compressors, pumps and fans.

Request a Desktop Assessment:

To assess the savings potential and ROI that Emissis Maxwell can deliver for your

organisation the following data is required to conduct an initial assessment:

• Type and location of facility (Pharmaceutical, Hotel, Data Centre, Office, etc)

• Brief description of the chiller (Chiller, heat Pump, Energy Recovery Unit)

• Manufacturer, model number and size of Chillers or Heat Pumps

• Square footage of site/facility